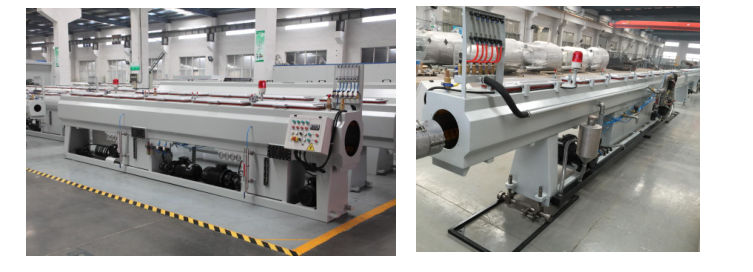

PPR cold and hot water pipe plastic pipe extruder production line

The PPR pipe production line adopts an efficient single-screw extruder and is equipped with a Siemens brand PLC automatic control system to achieve high output and extrusion stability. At the same time, the PE-RT, PEX, PB pipe line can be manufactured by changing the configuration unit. PPR pipe production line can adopt single pipe production line or double pipe production line, which has strong applicability. It can meet the requirements of resin production of various materials.

- Shipping:

Learn More

Features of ppr pipe production line equipment:

The man-machine interface has a high degree of automation.

The plasticizing effect of the screw is good.

The composite spiral head is used to effectively clear the material memory function.

Vacuum shaping and constant temperature control eliminate the pipe stress.

The co-extrusion head is used to increase the pipe color line.

Large extrusion volume, low melt temperature, uniform melt temperature.

Wide range of material processing.

PPR pipe product features

1. This machine is mainly used for pipe production with PPR resin as raw material

2. The design of slotted feeding barrel and barrier screw can improve the plasticizing effect.

3. The advantages of high extrusion volume, low melt temperature and uniform temperature.

4. Barrier type two-pole mixing, namely, screw and slotted barrel.

5. Equipped with a new type of secondary splitting mold, with the characteristics of low temperature and low pressure extrusion: water film type sizing sleeve to ensure high-speed production of pipes.

6. The production line is controlled by PLC programming. The ppr cold and hot water pipe production line is equipped with a good man-machine interface.

7. Optional marking line extrusion to produce color marking line pipes. The production line can change molds to produce PE pipes.

8. The random co-polypropylene production line is mainly used for the production of pipes with PP-R resin as raw material, and it is also suitable for the production of pipes with PP, PB, and PE resin as raw materials.

This unit uses SJ-65/33 as the extruder, equipped with corresponding molds, cooling devices, and traction devices for continuous and efficient extrusion of pipes. It has the characteristics of stable quality and convenient operation.

Model | Dia(mm) | Extruder | Speed(m/min) | Output(kg/h) | Total Motor(kw) | Size |

SRQG-63 | Ø20-Ø63mm | SJ-65×33 | 1.5-12 | 120 | 65 | 30×2.2×2.5m |

SRQG-110 | Ø20-Ø110mm | SJ-90×33 | 2-12 | 220 | 110 | 32×2.2×2.6m |

SRQG-160 | Ø63-Ø160mm | SJ-90×33 | 1.3-6 | 300 | 150 | 32×2.2×2.8m |