PVC Pipe Four Cavity Extrusion Machine

This production line is mainly used to produce PVC small and medium-sized pipes. The pipes produced are mainly used as cold-formed electrical casing, cable sheath, threading pipe, etc. Comparison of PVC one-out four-pipe production line with PVC double-pipe extrusion production line: Under the same output, electricity costs can be saved by 60%; air consumption can be saved by 80%; water consumption can be saved by 50% Realize chipless cutting and save raw materials.

- Shipping:

Learn More

Equipment composition and characteristics

Process flow of PVC pipe production line

The main production process: raw material + additives preparation → mixing → conveying and feeding → forced feeding → conical twin screw extruder → extrusion die → sizing sleeve → spray vacuum setting box → spray or immersion bath cooling water tank →Printing machine→Crawler tractor→cutting machine→pipe belling machine→pipe stacking rack→finished product inspection and packaging

(1) Mixing of raw materials: adding PVC stabilizers, plasticizers, antioxidants and other auxiliary materials into the high-speed mixer according to the proportion and process. After the materials move at high speed in the mixer, the strong self-friction generated makes the materials heat up. After reaching the set process temperature, it is discharged from the high-speed mixer to the cooling mixer to reduce the temperature to prevent plasticization and agglomeration. The cooled raw materials are added to the extruder by the feeder or manually to be extruded.

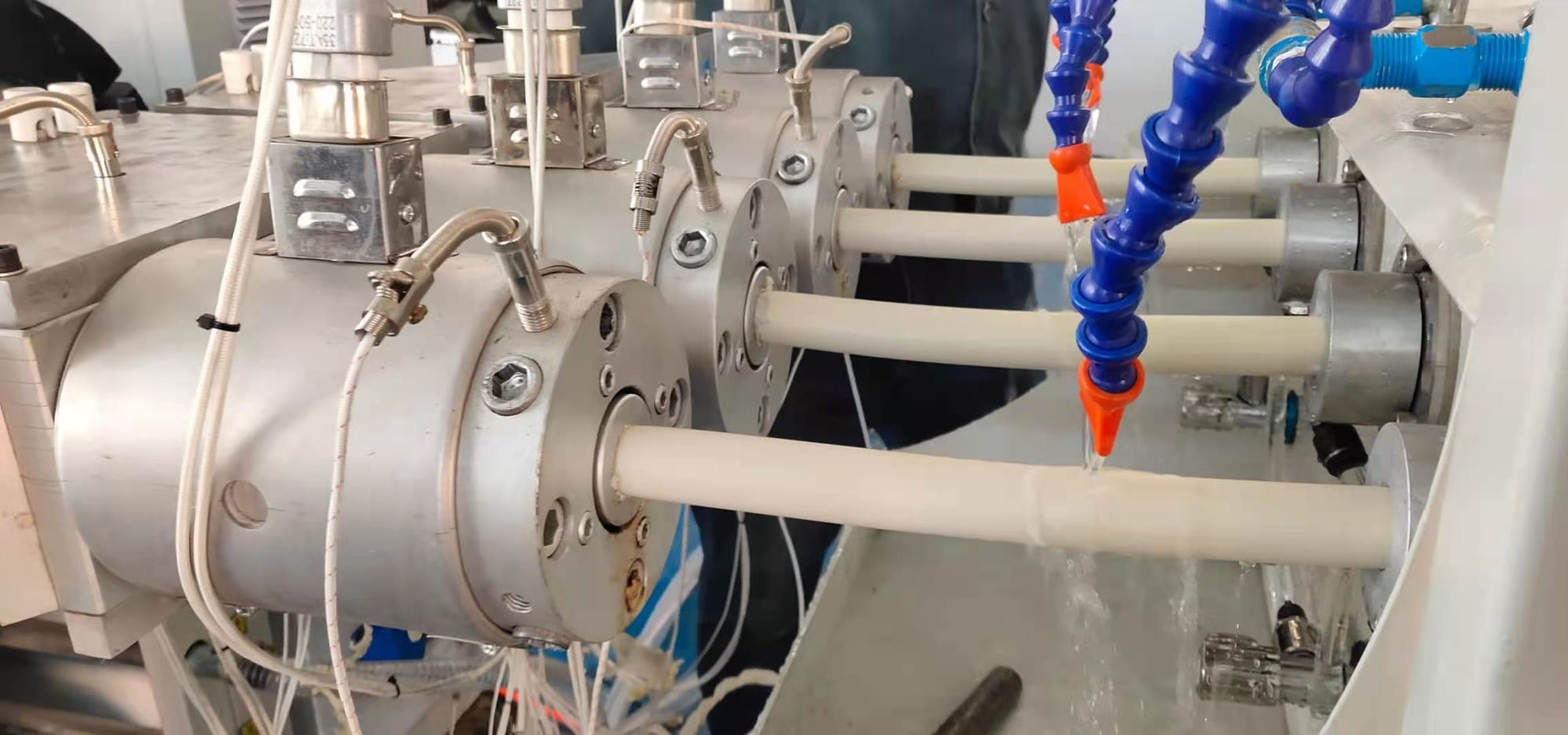

(2) Extruder part: The machine is equipped with a quantitative feeding device to match the extrusion volume with the feeding volume and ensure stable extrusion of the product. Due to the characteristics of the conical screw, the feeding section has a larger diameter, and the heat transfer area and shear speed of the material are relatively large, which is conducive to the plasticization of the material. The small screw diameter in the metering section reduces the heat transfer area and the melt The high shear speed enables the melt to be extruded at a lower temperature. When the screw rotates in the barrel, it plasticizes the PVC mixture and pushes it towards the machine head, so as to achieve compaction, melting, mixing and homogenization; and to achieve the purpose of exhaust and dehydration. The feeding device and screw drive device adopt frequency conversion speed regulation, which can realize synchronous speed regulation.

(3) Extrusion die head part: the PVC that is compacted, melted, mixed and homogenized, and the subsequent materials are pushed to the die head by the screw. The extrusion die head is a key part of pipe forming. In theory, the design of the die head for pipes with different composition content is different, so the appropriate extrusion die head should be selected according to the actual product application.

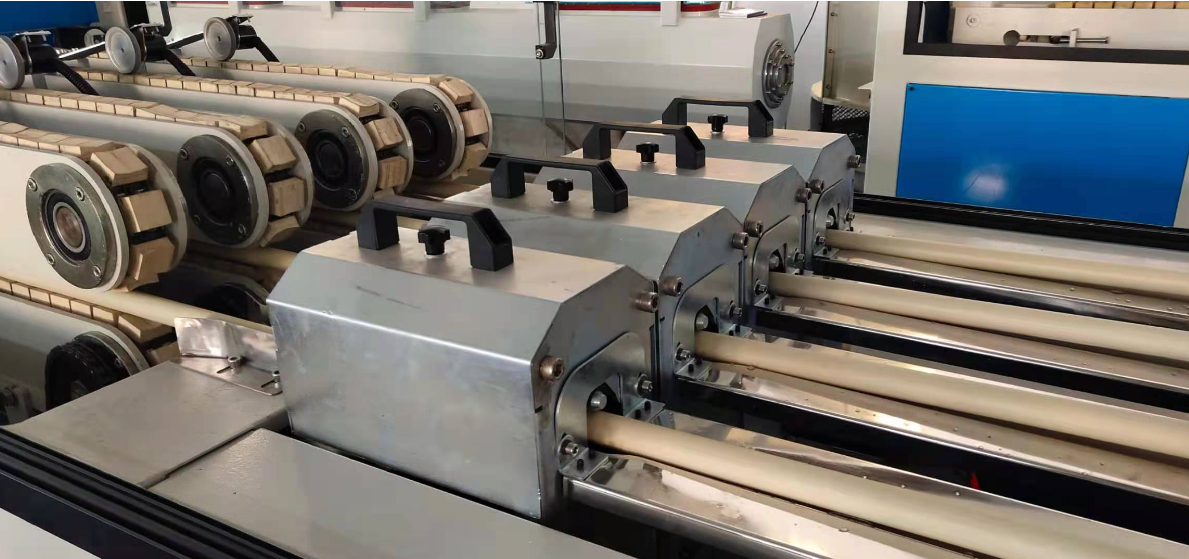

(4) The vacuum shaped water tank is used for the shaping and cooling of pipes. The vacuum shaped water tank is equipped with a vacuum system and a water circulation system for shaping and cooling. The stainless steel box body, circulating water spray cooling, and the vacuum shaped water tank are equipped with forward and backward moving devices and left and right. , Height adjustment device.

(5) The tractor is used to continuously and automatically draw the cooled and hardened pipe from the head. This machine adopts frequency conversion stepless speed regulation, which supports synchronous speed regulation with the extruder. The stability of the tractor is directly related to the uniformity of the wall thickness of the pipe after extrusion. ProWell Machinery has a wealth of design and manufacturing experience in this regard, which can well meet this requirement.

(6) Cutting machine: receive the signal given by the travel switch or other fixed-length devices, carry out automatic cutting, delay the turning frame, and implement flow production. The cutting machine keeps moving forward in synchronization with the pipe running during the cutting process. The electric and pneumatic drive is completed, and the cutting machine is equipped with a dust suction device to suck out the cutting debris in time and recover it.

(7) The turning action of the turning frame is realized by the air cylinder through the air circuit control. The turning frame is equipped with a limit device. When the cutting saw cuts the pipe, the pipe continues to be transported. After a delay, the cylinder enters the work to realize the turning. Action to achieve the purpose of unloading. After unloading, it will automatically reset after a few seconds delay, and wait for the next cycle.

Produced Pipe Specification: | Twin-pipe φ16 -50mm | Quadruple-pipe φ16 -32mm |

Production Line Speed: | 0.5-10m/min | 0.5-8m/min |

Power | 52kw | 75kw |

Extruder Model | SJSZ51/105 | SJSZ65/132 |

Total Length of Production Line: | about 20m | about 22m |