FRP Fiberglass Rebar Pultrusion production line

The FRP steel bar production line is a special pultrusion machine used to produce FRP steel bars with different specifications from 6mm to 32mm in diameter.

- Shipping:

Learn More

Product Description:

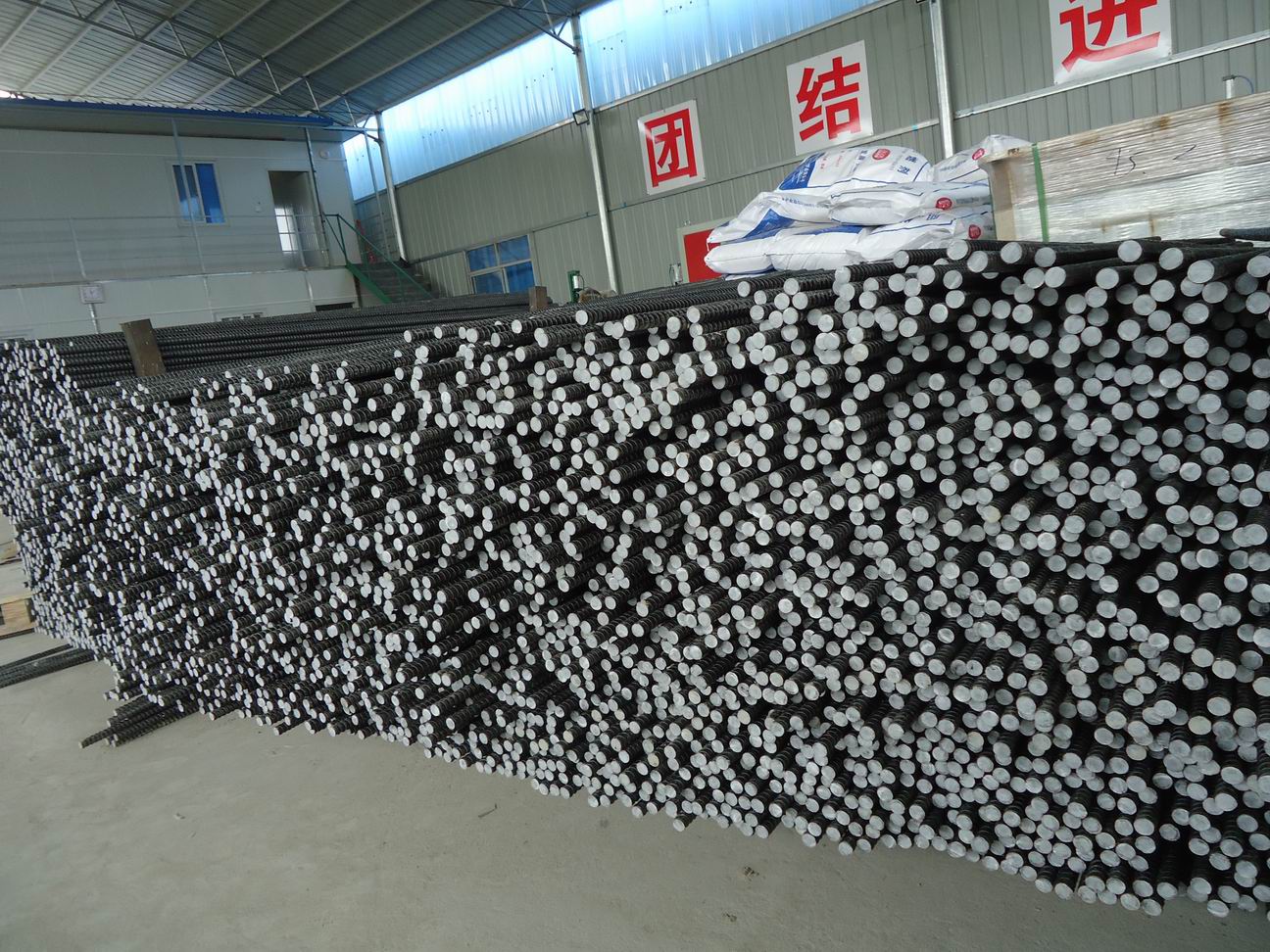

The FRP rebar production line is the special pultrusion machine used to produce FRP rebar with different specifications from diameter 6mm to 32mm. It can finish distributing roving, impregnation, pre-molding, winding, heating and curing, unwinding, fix-length cutting and pile up automatically.

The Newest production line can make 2pcs rebars at one time. so the production efficiency is high.

The line is the special pultrusion machine used to produce FRP rebar with different specifications. It can finish distributing roving, impregnation, pre-molding, winding, heating and curing, unwinding, fix-length cutting and pile up automatically.

A. Structure principle:

This line mainly consists of roving racks, resin bath, winding, heating oven, unwinding device, traction machine, cutting saw and racks for finished products.

1. Roving racks: Used to place the rolls, adopts the welding structure of steel plate, steel pipe and angle iron.

2. Resin bath: Welded by stainless steel material, there is press roller inside to make the roving DIP in the resin sufficiently.

3. Winding & unwinding device: Adopts gear wheel to drive the roller turn around the products, and wind the thread. This device adopts frequency conversion speed-regulated mode, adjust the rotate speed stepless.

4. Heating oven: Adopts cast aluminum heater, intelligent temperature controller to control the temperature. The heating box adopts mesh structure and it is easy to open it and clean the dropping resin, filled with insulation materials inside.

5. The material of mould is 45 or 40Cr painted with chrome on the surface.